The Backstory

The Backstory

When the US Occupational Safety and Health Administration (OSHA) adopted the Globally Harmonized System (GHS) of classification and labeling in 2015, it implemented the 3rd Revised Edition of the GHS. Released by the United Nations in 2009, this so-called ‘GHS Rev. 3’ was outdated the moment it was implemented in the US. In fact, four additional revisions have been released since then, and OSHA is finally ready to bring its Hazard Communication Standard (HCS) into the present day.

What’s Changing

OSHA recently announced that they plan to begin the regulatory rule-making process to update the HCS to GHS Rev 7 this coming March. Once the amended regulation has been agreed upon by OSHA, it will then proceed through a 90-day public comment period, before taking effect—final implementation date remains unknown at this time.

Implications

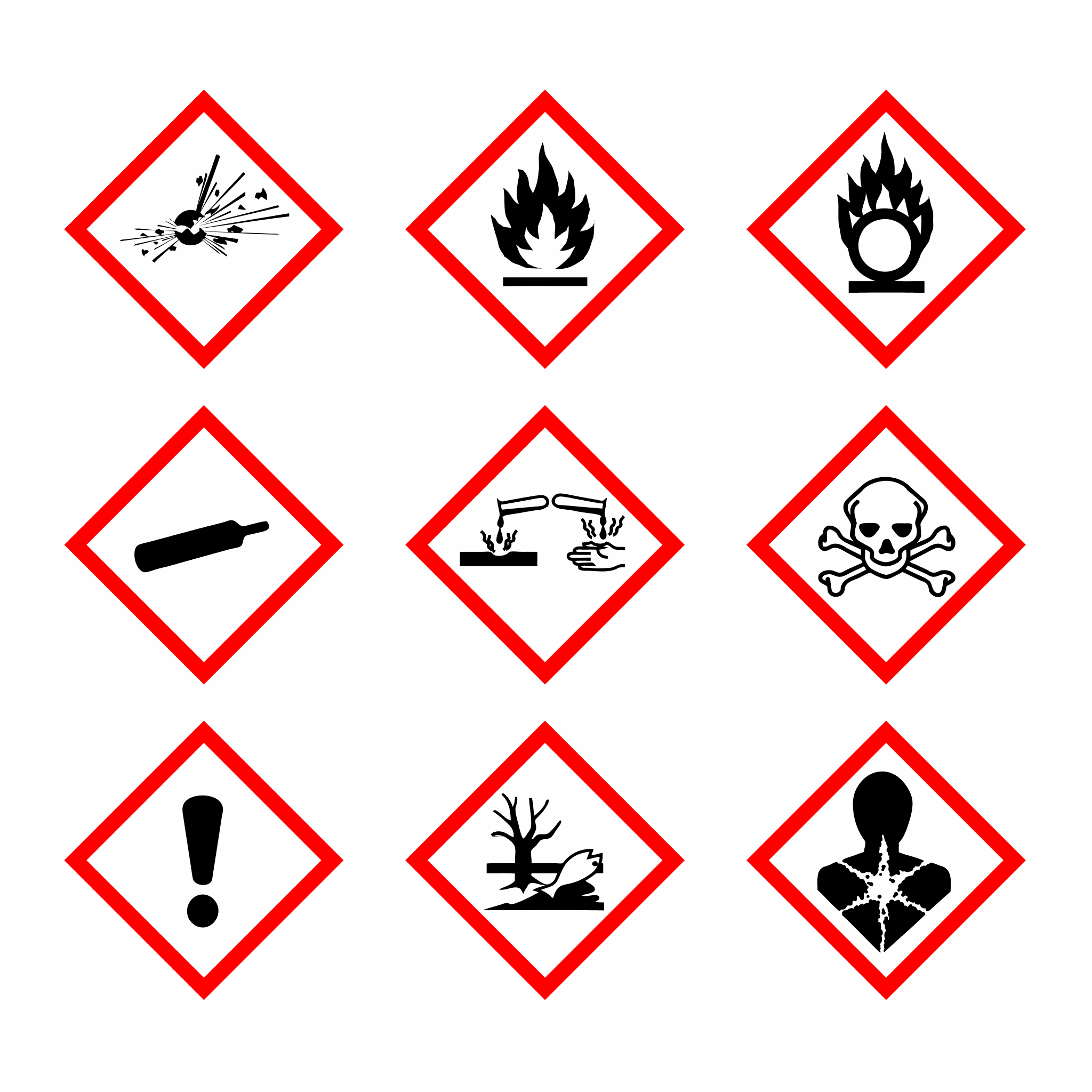

When OSHA implements ‘GHS Rev 7,’ it not only implements the changes outlined in the 7th Revised Edition of the GHS, but it also adds the numerous changes made to the GHS since then, through the 4th, 5th and 6th revisions of the GHS; this will include an array of significant changes, from the introduction of new physical hazard classifications, such as pyrophoric gases and non-flammable aerosols, to updated label guidance and the addition of new precautionary phrases. The changes are expected to be substantial, and many. Concise descriptions of the changes implemented with each successive revision have been published by the UN Economic Commission for Europe.

While it’s difficult to prepare for details that remain unknown, since it’s still unclear as to precisely what elements of each GHS revision will be adopted under the amended OSHA HCS, one thing is certain: significant changes are looming, and in a general sense, enterprises are wise to begin ensuring that they are resourced properly to respond; this includes, not only having the headcount to support the effort, but also the tools be efficient, such as software driven SDS authoring solutions, so that these changes can be made as seamlessly as possible.

Given the level of complexity of GHS SDSs and label requirements, the best way to protect yourself is with a compliance partner who has the depth and breadth of knowledge when it comes to SDS. “Generalist” regulatory companies who claim to be experts in all aspects of EHS needs, from barcoding to training, may be more of a liability than anything else when it comes to SDS and labels. It’s probably preferable to seek a compliance partner who has deep SDS domain expertise while simultaneously having strategic relationships with others with a similar depth of expertise in other domains.